Sub-Category

Model

Made In

Sprocket

These quality sprockets are made from the finest 545C high carbon steel and are then heat treated and hand finished to meet or exceed OEM standards. Outlasts many mild steel or surface hardened sprockets as much as two and three times over.

- Computer-designed to achieve ultimate strength at minimum weight

- JT combines leading-edge technology with top materials to produce the ultimate quality sprocket range with unbeatable value

- Every sprocket meets or exceeds the highest possible quality standards set for the motorcycle industry

- Sprockets are heat-treated and bead-blasted to reduce material surface tension

- Unless noted, rear sprockets made with top-quality-grade C45 high-carbon steel

- Computer-designed to achieve ultimate strength at minimum weight

- JT combines leading-edge technology with top materials to produce the ultimate quality sprocket range with unbeatable value

- Every sprocket meets or exceeds the highest possible quality standards set for the motorcycle industry

- Sprockets are heat-treated and bead-blasted to reduce material surface tension

- Unless noted, rear sprockets made with top-quality-grade C45 high-carbon steel

These quality JT sprockets are made from the finest 545C high carbon steel and are then heat treated and hand finished to meet or exceed OEM standards. Outlasts many mild steel or surface hardened sprockets as much as two and three times over.

JT Sprockets are made from the latest generation of computer design and control metal cutting equipment for maximum durability. Front sprockets are made from chromoly SCM420 steel alloy. All sprockets are heat-treated and hand-finished to meet or exceed the highest possible quality standards.

Currently available in 15 tooth size only, other sizes coming soon.

Made from the latest generation of computer design and control metal cutting equipment for maximum durability. Made exclusively from the finest Japanese 545C high carbon steel.

All sprockets are heat-treated and hand-finished to meet or exceed the highest possible quality standards.

These quality sprockets are made from the finest 545C high carbon steel and are then heat treated and hand finished to meet or exceed OEM standards. Outlasts many mild steel or surface hardened sprockets as much as two and three times over.

This kit will replace your stock sprocket bolts and nuts with new hardware.

Factory Honda replacements in a convenient kit.

For all years.

- Machined from impact and wear resistant chromoly steel

- Heat treated, then finished with a nickel coating for corrosion resistance

- Constructed of the highest quality 1045 high-carbon steel

- Exclusive heat treatment and quenching process for strength and durability

- Nearly all machines come equipped from the factory with this sprocket

- The strongest, longest lasting steel replacement sprocket available

High quality steel front sprocket

For reference, the stock gearing for the WR250R is 13/43 while the X model runs 13/42 stock gearing.

Quality JT sprockets are made from the finest 545C high carbon steel and are then heat treated and hand finished to meet or exceed OEM standards. Outlasts many mild steel or surface hardened sprockets as much as two and three times over.

Available in a 15T

- Computer-designed to achieve ultimate strength at minimum weight

- JT combines leading-edge technology with top materials to produce the ultimate quality sprocket range with unbeatable value

- Every sprocket meets or exceeds the highest possible quality standards set for the motorcycle industry

- Sprockets are heat-treated and bead-blasted to reduce material surface tension

- Unless noted, rear sprockets made with top-quality-grade C45 high-carbon steel

- Size 38T

- Stock gearing uses a 15 tooth sprocket

- Use a 13 tooth sprocket for REALLY low off-road gearing

- Use a 14 tooth sprocket for off-road performance

- A 16 tooth sprocket will give you lower RPM at highway or street speeds

JT Sprockets is the world's leading manufacturer of aftermarket sprockets, constantly raising the industry's standards for quality and service. Made exclusively from the finest Japanese 545C high carbon steel

- Computer-designed to achieve ultimate strength at minimum weight

- JT combines leading-edge technology with top materials to produce the ultimate quality sprocket range with unbeatable value

- Every sprocket meets or exceeds the highest possible quality standards set for the motorcycle industry

- Sprockets are heat-treated and bead-blasted to reduce material surface tension

- Unless noted, front sprockets are made with C45 steel and SCM415 chromoly steel alloy; rear sprockets made with top-quality-grade C45 high-carbon steel

Quality steel sprockets and EK SROZ2 525 O-Ring chain. Available in gear ratio choices from - 13/42 to 15/46. EK SROZ2 525 chains come in 120 link length and may have to be cut down to fit. They also come with rivet type master links. Clip type links are available below.

13 and 14 Tooth sprockets require a smaller retainer

- Use a rear sprocket with a higher number of teeth for quicker acceleration and technical offroad trails.

- Use a rear sprocket with a lower number of teeth for lower engine rpm's at highway speeds.

- Stock size is 50 teeth.

We recommend using the Rear Sprocket Bolt Kit when installing most aftermarket sprockets on your TW.

Quality steel front sprockets. Choose 525 or 520. Also available 'Wide Boss' JTF438 520 sprockets.

All 520 sprockets require a new retainer plate, please add on if purchasing this size.

High quality sprockets

- Stock size is 14 tooth

- Add teeth for highway riding

- Subtract teeth for low end gearing

Counter shaft sprocket replacement requires the removal of the left side case cover. A new gasket may be required. This is also a great time to replace that leaking oil seal!

These quality JT sprockets are made from the finest 545C high carbon steel and are then heat treated and hand finished to meet or exceed OEM standards. Outlasts many mild steel or surface hardened sprockets as much as two and three times over.

Quality JT sprockets are made from the finest 545C high carbon steel and are then heat treated and hand finished to meet or exceed OEM standards. Outlasts many mild steel or surface hardened sprockets as much as two and three times over.

Individual 14T, 15T or 16T front sprockets.

JT Sprockets are made from the latest generation of computer design and control metal cutting equipment for maximum durability. Front sprockets are made from chromoly SCM420 steel alloy. All sprockets are heat-treated and hand-finished to meet or exceed the highest possible quality standards.

JT Sprockets is the world's leading manufacturer of aftermarket sprockets, constantly raising the industry's standards for quality and service. JT Sprockets are the only sprocket manufacturer using the ultra-durable high carbon C49 steel for rear sprockets.

Stock Gearing: 15/45-520x112

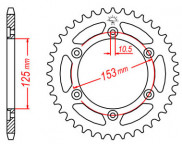

Rear Sprocket

Note: 2002 and later models have a 10mm sprocket bolts. 2000-2001 models have 8mm sprocket bolts.

JT steel rear sprockets are manufactured using only the finest grade of C49 high carbon steel.

Two styles of rear sprocket were used on the DR350. The 90-95 'S' and 'SE' (street legal) models have a cush drive hub. The 96-99 'S' and 'SE' as well as all of the 'dirt only' models have a non-cush rear hub. Select your sprocket accordingly. If you are not sure, look at your bike. If the sprocket is bolted directly to the wheel hub you have a non-cush model. If your sprocket is bolted to a separate sprocket carrier you have a cush drive model.

Quality steel rear sprockets.

Color may vary based on manufacturer availability, quality will not be compromised.

Quality steel rear sprockets. Choose 525 or 520. 41T to 50T

48 and 50 sprockets require removal or modification of your lower chain guide.

Chain Size Recommendations:

- 110 link chain for a 42 tooth rear sprocket

- 112 link chain for a 46 tooth sprocket

- 120 link for the 48 and above sprockets.

- 120 link chain will have to be cut to the proper size for the 48 and 50.

*Actual sprocket color may differ from image shown.

Now you can have minimum output shaft wear, minimum chain drive wear with the FRITZCO DRIVELINE sprocket. The design of their sprockets provide correct chain alignment, allows for full spline contact with the XR650L's output shaft, fit the counter shaft either way, and straight up no hassle installation with the OEM two bolt retainer and fasteners (except 13 tooth that comes with it's own quick change retainer). Their sprockets are machined from alloy steel that is comparable in every way to OEM Honda and the best offered by other manufactures. The sprockets are then given a heat treatment that provides a compatible sprocket for the Honda output shaft and longest wear life possible.

A way to double the sprockets life would be to have a sprocket that fits on the shaft either way so both sides of the teeth can be used. Bear in mind you can't wear one side of the teeth all the way through, then flip the sprocket, and expect double life. You must reverse when a normal wear pattern develops.

16 tooth sprocket is the biggest front sprocket that will run with the standard 110 link chain and 45 tooth rear sprocket on an XR650L

The OEM cover will require modifying to use the 16 tooth sprocket on your XR650L.

These quality JT sprockets are made from the finest 545C high carbon steel and are then heat treated and hand finished to meet or exceed OEM standards. Outlasts many mild steel or surface hardened sprockets as much as two and three times over.

For reference, the stock gearing for the WR250R is 13/43 while the X model runs with a 13/42 stock configuration because of the SM wheels/tires. Both use a 108 link chain with the stock gearing.

The JT rear sprockets listed are made from the finest 545C high carbon steel and are then heat treated and hand finished to meet or exceed OEM standards. Outlasts many mild steel or surface hardened sprockets as much as two and three times over.

Limited availability on Aluminum from PBI. Manufactured from aircraft 7075 T651 Plate Aluminum.

If you want the additional low-end grunt that the 46, 48 or 50 tooth rear sprocket will give you, you will need longer chain as well.

New Rear Sprockets require new Sprocket Bolts because of a difference in the holes vs. the stock bolts.

High quality steel front sprockets from 12T to 14.

Color may vary based on manufacturer availability, quality will not be compromised.

High quality steel front sprockets.

- Made exclusively from the finest Japanese SCM420 chromoly steel alloy

- Heat treated and hand finished to meet or exceed O.E.M. standards

- Outlasts any mild steel or surface hardened sprocket as much as two and three times over

Quality steel sprockets and EK SRO6 O-ring chain. We put them together to make a complete, affordable kit. Chain comes with clip type master link.

Individual 14T, 15T or 16T front sprockets.

JT Sprockets are made from the latest generation of computer design and control metal cutting equipment for maximum durability. Front sprockets are made from chromoly SCM420 steel alloy. All sprockets are heat-treated and hand-finished to meet or exceed the highest possible quality standards.

Polyurethane drive cushions for the DR. Polyurethane has a higher abrasion, cut, and tear resistance than rubber as well as much better resistance to chemical breakdown. This will offer longer life and better damping when compared to the stock rubber cushions.

Polyurethane drive cushions for the KLR650. Polyurethane has a higher abrasion, cut, and tear resistance than rubber as well as much better resistance to chemical breakdown. This will offer longer life and better damping when compared to the rubber counterpart.

Replace these any time you feel excessive play in the sprocket hub.

Excessively worn dampers can cause the cush hub bearing to fail - which will ruin your sprocket carrier.

Sold as a full set.

The KLR650 is rather hard on the cush drive rubbers. Replace these any time you feel excessive play in the sprocket hub. Excessively worn dampers can cause the cush hub bearing to fail - which will ruin your sprocket carrier.

Counter shaft seals can wear out over time. Replace it with a genuine Yamaha counter shaft oil seal.

A pack of 10 Fuji style lock nuts to put on the sprocket of your KLR650. These are an 8 mm, flanged type nut that will keep your sprocket snug and tight.

Premium drive belts offer longer life than standard ones. A worn drive belt can affect your scooter's top speed.

Replace these any time you feel excessive play in the sprocket hub.

Excessively worn dampers can cause the cush hub bearing to fail - which will ruin your sprocket carrier.

Sold as a full set.

The DR650 is rather hard on the cush drive rubbers. Replace these any time you feel excessive play in the sprocket carrier hub. Excessively worn dampers can cause the cush hub bearing to fail - which will ruin your sprocket carrier. Sold as a set of 6 rubber dampers.

Replace these any time you feel excessive play in the sprocket hub.

Excessively worn dampers can cause the cush hub bearing to fail - which will ruin your sprocket carrier.

Sold as a full set.

- CNC machined anodized axle blocks

- Made of A6061-T6 aluminum

- Rotate using the forward and reverse positions, able to offset axle shaft 13mm in reverse position. (Mini size is 11mm)

- Scales on both sides of axle block for easy adjusting