The pictures used here are for a DR650 fork solution upgrade. However, the principles apply to any damper rod type fork.

The stock DR650 front suspension is hopelessly soft and under damped. How bad is it? The stock fork springs are progressive. The first part of fork travel the springs have a .38kg/mm spring rate. At about 7 inches into the suspension travel the progressive springs transition to a .53kg/mm rate. This 38/53 spring rate might work OK if the transition happened earlier in the stroke - say around 3 inches. As it is, the forks have already blown through most of their travel by the time the stiffer part of the spring starts doing anything. The end result is most of the time the DR is essentially floating along on .38 springs. As if this wasn't bad enough, the damper rods in the forks each have 4 big compression bleed holes. This means we have wimpy compression damping to go along with our limp springs.

Luckily, it isn't difficult to remedy this situation. There is a wide range of fork springs available and Race Tech cartridge emulators do a great job for solving the damping issues. With that in mind I thought I'd do a little pictorial 'how to'.

I like to start by first loosening the top caps from the forks. This is easier to do while the forks are still bolted to the bike.

However, you will want to loosen the top triple clamp pinch bolts to make loosening the caps easier.

Do not remove the cap at this time just loosen it a turn or so.

Next, support the bike with the front wheel off the ground and remove the front wheel and the brake caliper.

After removing the stays that hold the speedometer cable and the brake hose you can loosen the bottom triple clamp bolts and remove the forks from the bike.

Loosen the fork boot clamps and remove the fork boots.

Now you can remove the top caps from the fork tubes along with the stock preload spacers.

The cap comes off easy because you so wisely loosened it up when it was still on the bike.

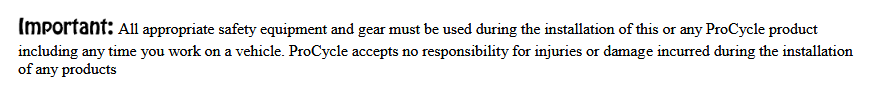

Remove the springs and pour the fork oil into a drain pan.

With the forks upside down over the drain pan work them through their entire travel to pump out the remaining fork oil.

Leave the forks upside down over a drain pan so all the fork oil can drain out. Don't be in a hurry. Give them plenty of time to drain.

Doing the rest of the disassembly will be easier if you don't have residual oil spilling out.

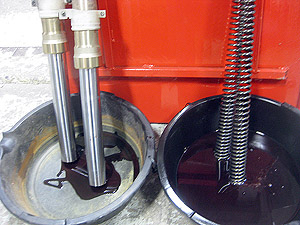

Using a small screwdriver remove the seal retaining clip.

Insert the damper rod holding tool down into the top of the fork. The hex will engage with the socket on the top of the damper rod.

Use a screwdriver or piece of metal rod to keep the holding tube from turning. Put a 6mm hex key on the bolt in the bottom of the fork and remove the bolt.

The bolt will probably be very tight. Use an air wrench if you have one. If not, I've had good results smacking the hex key with a mallet to break it loose.

I like to use a bit of heat to help unstick the fork seals. If you have a heat gun warm up the top of the fork slider around the area of the fork seals.

You don't have to do this but it usually makes the seals come out much easier.

Holding the fork tube in one hand and the slider in the other pull them apart with a repeating sliding action.

The aim is to drive the fork seals out of the top of the fork slider with the impact of the tubes sliding apart.

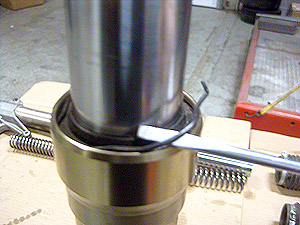

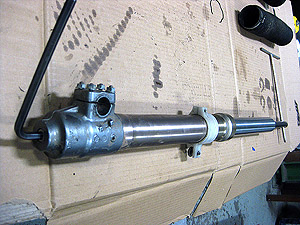

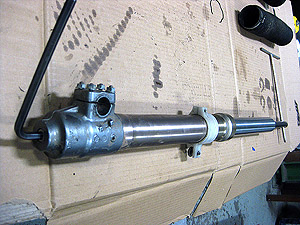

Once it's apart note the order of the pieces. 1-Cup 2-damper rod 3-lower bushing 4-upper bushing 5-washer 6-oil seal 7-dust seal

Remove everything except the lower bushing (unless you are replacing it).

Now is a good time to inspect the bushings. The lower bushing has a Teflon coating in the outside. The upper bushing has Teflon on the inside.

Check for any sign that the Teflon is wearing through, peeling, scraped, etc. any damage to the Teflon indicates the bushing should be replaced.

Even if they look pretty good there's nothing wrong with putting fresh bushings in now while the forks are apart.

Here's an optional trick - surface conditioning of the for tubes.

Take some 400 grit wet/dry sandpaper with some light oil (fork oil, WD40, ATF, etc.) and give the fork tubes a good rub down.

This will smooth the edges of any tiny pits and will lessen the sliding friction. I've found this to be especially effective with forks that looked perfect but still weeped oil at the seals.

The tubes are chrome plated and very hard; 400 paper is not going to hurt anything. Race Tech will use 240 wet/dry paper to help make fork tubes more slippery.

I find it's easier to do this on the lathe. I can get a nice crosshatch pattern just like honing a cylinder. Doing it by hand is just as effective.

Time to clean everything up. If you don't have access to a solvent tank kerosene works very well to rinse off the old oil and dirt.

Do NOT use gasoline. Finish the cleanup with hot soapy water and dry the parts thoroughly.

Next we modify the damper rod according to the Race Tech Emulator instructions.

Notice the 4 compression damping holes in the bottom of the damper rod.

The spring is a 'top out' spring. It softens the impact when the suspension is fully extended.

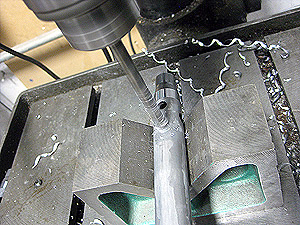

We need to drill 2 more 5/16 holes. Place the new holes above the first pair of holes.

Making the holes too close together could weaken the damper rod. Just extend the pattern of the existing holes.

Clean up any metal burrs from the drilling. You don't want little metal pieces getting loose inside the forks.

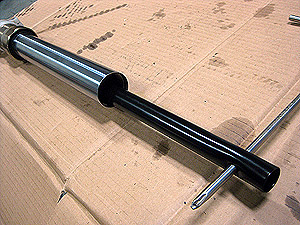

Yay! Time to start putting things back together. Assemble the damper rod. This bike is getting 'factory lowered'.

That means the preload spacer that was originally on top of the fork spring is moved to a position just under the head of the damper rod.

Moving the spacer makes the damper rod and fork slider ride higher in the suspension travel which lowers the front end.

If your forks are going back together at standard height leave the preload spacer out.

Slip the damper rod and top out spring down into the fork tube. Put the nylon cup back on the bottom.

Slide the fork tube and damper rod down into the the fork slider. Apply some low strength thread lock compound to the bottom bolt.

Hold the damper rod with the holder tool and tighten up the bottom bolt.

Next install the upper bushing, washer and fork seal.

Here's a reminder of the assembly order.

Use a seal driver to tap the seal down into the slider until it bottoms out.

If you don't have access to a seal driver a piece of 2" ABS or PVC pipe can do the job.

Install the dust seal and use the seal driver to seat it into the slider.

If everything is properly seated into place the retaining clip will easily pop into its groove.

Now we can add the fork oil. Measure out 19 ounces of 10w fork oil and pour it into the top of the fork tube.

Before the Emulator goes in I like to verify the preload setting on the poppet valve. Loosen the locknut and back out the allen head screw until the spring is loose.

Then slowly turn the allen screw in until there is no end play (but also no preload) in the spring. Then turn the screw in 2 full turns and secure the locknut.

I like to use 2 turns as a starting point. More turns will give you more compression damping. Fewer turns will give a softer plusher ride.

You can make future tuning adjustments by removing the fork springs and fishing the Emulators out with a hooked wire or a strong magnet on a length of hose.

Drop the Emulator into the fork tube and put the spring in on top of it. For this build I'm installing .55 kg/mm fork springs.

Sometimes the Emulator won't end up sitting flat on the damper rod like it should.

When this happens the spring will seem like it's not going all the way down in the fork. If you rotate the spring it will move the Emulator into the correct position.

Now that the spring is in we can make measurements to determine the correct length for the preload spacers. Sometimes this is easier to do with the forks back on the bike.

For this bike I want to start out at about 3/4" of preload. Luckily, the fork cap screws down into the tube by just about that amount.

That means is I want 3/4" of preload I need the top of the spacer to be flush with the top of the fork tube.

The top of the spring is almost exactly 1" below the top of the tube so I need a 1" spacer. This would be longer if I had not installed Emulators.

If I had not set up the forks in 'factory lowered' configuration I would leave out the original preload spacer and cut a much longer preload spacer to give me the desired amount of preload.

If you haven't done so already, put the fork tubes back on the bike. Leave the top triple clamp bolts loose, install the top caps and tighten them up.

Tighten the triple clamp pinch bolts and reinstall the front wheel, caliper and the stays that hold the speedo cable and brake hose.

Tighten the axle and pay special attention to the axle clamp on the right hand side. The arrow should point up.

The top nuts should be tightened first so there is no gap at the top. The bottom nuts should be tightened last.

There will be some gap but only at the bottom.