Sub-Category

Model

Made In

Sprocket

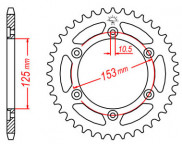

JT steel rear sprockets are manufactured using only the finest grade of C49 high carbon steel.

Two styles of rear sprocket were used on the DR350. The 90-95 'S' and 'SE' (street legal) models have a cush drive hub. The 96-99 'S' and 'SE' as well as all of the 'dirt only' models have a non-cush rear hub. Select your sprocket accordingly. If you are not sure, look at your bike. If the sprocket is bolted directly to the wheel hub you have a non-cush model. If your sprocket is bolted to a separate sprocket carrier you have a cush drive model.

Available for stock gearing, 45 tooth rear sprocket

The 50 tooth rear sprocket will give you much lower gearing for off-road use. You will need a longer chain for this rear sprocket, please order the 130 link chain to fit with this larger sprocket, it may need to be shortened to fit correctly.

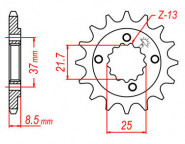

Individual 14T, 15T or 16T front sprockets.

JT Sprockets are made from the latest generation of computer design and control metal cutting equipment for maximum durability. Front sprockets are made from chromoly SCM420 steel alloy. All sprockets are heat-treated and hand-finished to meet or exceed the highest possible quality standards.

- Constructed of the highest quality 1045 high-carbon steel

- Exclusive heat treatment and quenching process for strength and durability

- Nearly all machines come equipped from the factory with this sprocket

- The strongest, longest lasting steel replacement sprocket available

- Computer-designed to achieve ultimate strength at minimum weight

- JT combines leading-edge technology with top materials to produce the ultimate quality sprocket range with unbeatable value

- Every sprocket meets or exceeds the highest possible quality standards set for the motorcycle industry

- Sprockets are heat-treated and bead-blasted to reduce material surface tension

- Unless noted, front sprockets are made with C45 steel and SCM415 chromoly steel alloy; rear sprockets made with top-quality-grade C45 high-carbon steel

- Computer-designed to achieve ultimate strength at minimum weight

- JT combines leading-edge technology with top materials to produce the ultimate quality sprocket range with unbeatable value

- Every sprocket meets or exceeds the highest possible quality standards set for the motorcycle industry

- Sprockets are heat-treated and bead-blasted to reduce material surface tension

- Unless noted, front sprockets are made with C45 steel and SCM415 chromoly steel alloy; rear sprockets made with top-quality-grade C45 high-carbon steel

- Computer-designed to achieve ultimate strength at minimum weight

- JT combines leading-edge technology with top materials to produce the ultimate quality sprocket range with unbeatable value

- Every sprocket meets or exceeds the highest possible quality standards set for the motorcycle industry

- Sprockets are heat-treated and bead-blasted to reduce material surface tension

- Front sprockets are made with C45 steel and SCM415 chromoly steel alloy.

- Quality, design and OEM proven technology are the same as used for what is supplied to the motorcycle manufacturers

Individual 14T, 15T or 16T front sprockets.

JT Sprockets are made from the latest generation of computer design and control metal cutting equipment for maximum durability. Front sprockets are made from chromoly SCM420 steel alloy. All sprockets are heat-treated and hand-finished to meet or exceed the highest possible quality standards.

For reference, the stock gearing for the WR250R is 13/43 while the X model runs with a 13/42 stock configuration because of the SM wheels/tires. Both use a 108 link chain with the stock gearing.

The JT rear sprockets listed are made from the finest 545C high carbon steel and are then heat treated and hand finished to meet or exceed OEM standards. Outlasts many mild steel or surface hardened sprockets as much as two and three times over.

Limited availability on Aluminum from PBI. Manufactured from aircraft 7075 T651 Plate Aluminum.

If you want the additional low-end grunt that the 46, 48 or 50 tooth rear sprocket will give you, you will need longer chain as well.

New Rear Sprockets require new Sprocket Bolts because of a difference in the holes vs. the stock bolts.

High quality sprockets

- Stock size is 14 tooth

- Add teeth for highway riding

- Subtract teeth for low end gearing

Counter shaft sprocket replacement requires the removal of the left side case cover. A new gasket may be required. This is also a great time to replace that leaking oil seal!

- Computer-designed to achieve ultimate strength at minimum weight

- JT combines leading-edge technology with top materials to produce the ultimate quality sprocket range with unbeatable value

- Every sprocket meets or exceeds the highest possible quality standards set for the motorcycle industry

- Sprockets are heat-treated and bead-blasted to reduce material surface tension

- Unless noted, rear sprockets made with top-quality-grade C45 high-carbon steel

- Use a rear sprocket with a higher number of teeth for quicker acceleration and technical offroad trails.

- Use a rear sprocket with a lower number of teeth for lower engine rpm's at highway speeds.

- Stock size is 50 teeth.

We recommend using the Rear Sprocket Bolt Kit when installing most aftermarket sprockets on your TW.